Packaging Machine Controller

Programmable Packaging Machine Controller

SS-PLC-V3

The SS-PLC-V3 controller by System Software is a dedicated controller designed for the Form fill seal / Vertical Form fill seal machine control. This controller is pre-programmed to control the operations of the pneumatic pouch packaging machines. This Controller is has direct interface to machine’s operations making it simple, robust and ready-to-use solution for automation of the VFFS Packaging Machines.

Specifications:

| Parameter | Details |

|---|---|

| Operating Voltage | 24VDC, 5W |

| Digital Outputs | 16x digital outputs PNP 2 x high speed & high current outputs for Clutch Brake Control |

| Digital Inputs | 10x digital inputs PNP |

| Communication | 1 x RS232 Modbus RTU |

| Timings | 10ms and 1ms resolution settable timers |

| Interface | Interface with standard HMI over Modbus RTU protocol |

| Size | 209mm x 111mm x 45mm ( L x W x D ) |

| Mounting | Wall Mount on M3 x 4 screws |

Key Features:

- Dedicated Control Action: Controller is specifically designed to control the operations of the VFFS packaging machine.

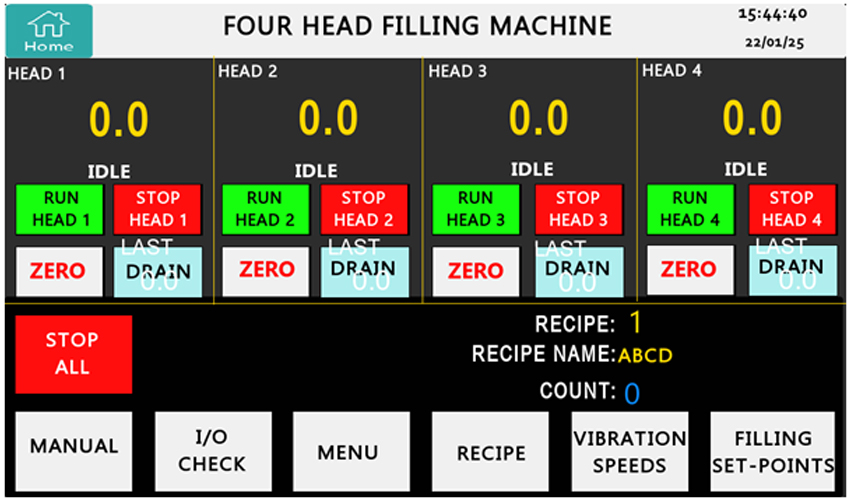

- HMI Integration: An intuitive user-friendly interface for easy operation and control.

- Flexible Programming: The machine logic can be changed and customized as per the requirement.

- Robust Design: Designed to perform well over a long period in industrial settings.

- High Current Outputs: Direct switching of DC solenoid coils, clutch and brake coils.

Applications:

1. Clutch Brake Auger Filler VFFS Packaging Machines:

Output List

- Film Pulling – via VFD / Stepper Drive

- Horizontal Sealer Jaw

- Vertical Sealer Jaw

- Batch cutter

- Perforation cutter

- Nitrogen gas flushing

- Printer

- Unwinding Motor

- Alarm Output

- Auger Filler Clutch

- Auger Filler Brake

- Screw Feeder Conveyor

Input List

- Start Push-Button

- Stop Push-Button

- Photomark sensor

- Unwinding motor start sensor

- Unwinding motor stop sensor

- Material Level Sensor

- Emergency Stop Switch

- Paper end Sensor

- Auger Pulse-Counter / Encoder / Fork Sensor

Settable Parameters

- Film length

- Photomark delay and blanking time

- Jaw operation delay and on-time

- Batch cutter operation delay, on-time and strip count

- Perforation cutter operation delay, on-time

- Printer operation delay, on-time

- Unwinding motor time-out delay

- Nitrogen gas flush operation delay, on-time

- Auger Counts / Auger On-Time

- Filling sequence – Fill before seal / Fill after seal

Functional parameters are recipe-wise settable. The user can create his recipes based on the pouch length and seal requirements.

2. Volumetric Cup-Filler VFFS Packaging Machines:

Output List

- Film Pulling – via VFD / Stepper Drive

- Horizontal Sealer Jaw

- Vertical Sealer Jaw

- Batch cutter

- Perforation cutter

- Nitrogen gas flushing

- Printer

- Unwinding Motor

- Alarm Output

- Disc Motor

- Feeder Conveyor

Input List

- Start Push-Button

- Stop Push-Button

- Photomark sensor

- Unwinding motor start sensor

- Unwinding motor stop sensor

- Material Level Sensor

- Emergency Stop switch

- Paper end sensor

- Disc Proxy Sensor

Settable Parameters

- Film length

- Photomark delay and blanking time

- Jaw operation delay and on-time

- Batch cutter operation delay, on-time and strip count

- Perforation cutter operation delay, on-time

- Printer operation delay, on-time

- Unwinding motor time-out delay

- Nitrogen gas flush operation delay, on-time

- Disc Drop Count, Disc operation delay, Disc operation mode – continuous / intermittent

- Filling sequence – Fill before seal / Fill after seal

Functional parameters are recipe-wise settable. The user can create his recipes based on the pouch length and seal requirements

3. Piston Filler Packaging Machines:

Output List

- Film Pulling – via VFD / Stepper Drive

- Horizontal Sealer Jaw

- Vertical Sealer Jaw

- Batch cutter

- Perforation cutter

- Nitrogen gas flushing

- Printer

- Unwinding Motor

- Alarm Output

- Piston Cylinder forward stroke

- Piston Cylinder reverse stroke

- Feeder Conveyor

Input List

- Start Push-Button

- Stop Push-Button

- Photomark sensor

- Unwinding motor start sensor

- Unwinding motor stop sensor

- Material Level Sensor

- Emergency Stop switch

- Paper end sensor

- Piston cylinder home position reed switch

- Piston cylinder forward position reed switch

Settable Parameters

- Film length

- Photomark delay and blanking time

- Jaw operation delay and on-time

- Batch cutter operation delay, on-time and strip count

- Perforation cutter operation delay, on-time

- Printer operation delay, on-time

- Unwinding motor time-out delay

- Nitrogen gas flush operation delay, on-time

- Piston Drop Count, piston operation delay

- Filling sequence – Fill before seal / Fill after seal

Functional parameters are recipe-wise settable. The user can create his recipes based on the pouch length and seal requirements