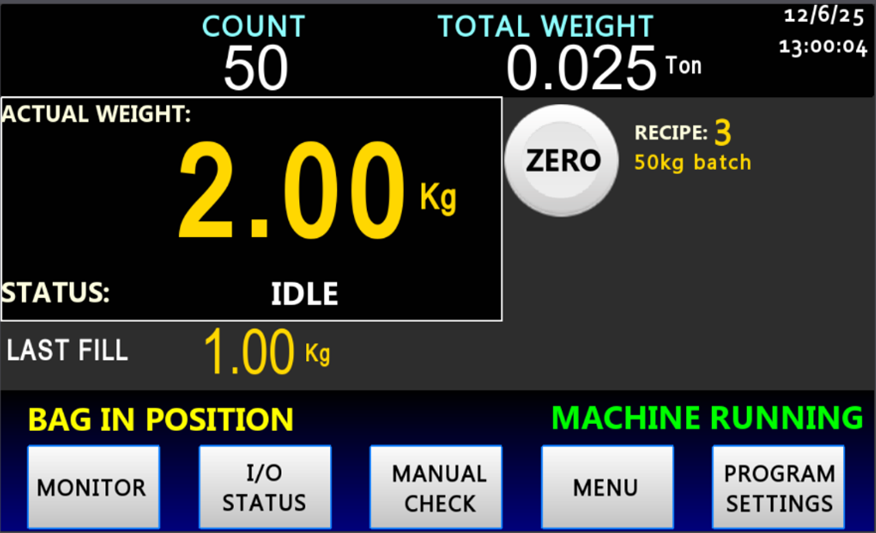

Bagging Controller

SS-UNI-0503 Loadcell Controller

The bagging machine control system is a ready-to-use product developed for weighing based net/gross bagging machines. All operations of the bagging machine are controlled in this panel. All operational parameters are preset and developed as per the machine’s logic. This gives great flexibility for the OEMs to use this panel directly for their bulk weighing and bagging machines.

Specifications:

| Loadcell Interface | 1 x loadcell interface. (4-wire 350ohm x 4 nos max) |

|---|---|

| A-D Converter | 24-bit Sigma-Delta AD Converter with settings for: |

| Programmable Gain | Digital Filter |

| Usable Counts | Sampling Speed |

| Digital Outputs | 5 x Digital Outputs PNP |

| Analog Outputs | 1 x 0-10Vdc Analog Output of 10-bit Resolution |

| Digital Inputs | Digital Inputs |

| User Interface | Interface with standard HMI over RS-485 Modbus RTU Protocol |

| Datalogging | Datalog of Fill-Weight with date and time stamp. Can be exported to .csv file |

| Size | 120mm x 65mm x 110mm ( L x W x D ) |

| Mounting | 35mm DIN Rail Mount |

System Features:

- Control panel in MS Powder coating with standard wiring and printed ferrules.

- Available with VFD for filling motor speed control.

- Available with VFD for filling motor speed control.

- Plug-n-Play system. Direct connection to machine outputs and inputs via terminal connections.

Input Functions

- Start Trigger

- Emergency Stop

- Bag Lock Feedback

Output Functions

- Coarse Gate

- Fine Gate

- Bag Clamp

- Material Drain Valve

- Ready Lamp

Program Functions

- Target Weight, Coarse Weight & In-flight weight setpoints

- Delay and Action times for material drain valve, bag clamp, weight verification, process start

- Upto 50 recipes can be configured

- Easy to use intuitive HMI

- Weight totalizer and production count totalizer options

- Datalogging option

Applications:

- Bagging Machines

- Bulk Filling Machines

- Nett Filling Machines

- Gross Filling Machines

- Auger based bag filling Machines

- Gravity Bag Filling Machines